What's Inside?

Corsair uses a Yate Loon 14cm, 25mm deep ball bearing fan to do its cooling. The "H" in the D14BH-12 means it's a high flow 14cm fan that can shift a whopping 140CFM at 2,800RPM with an ear aching noise of 48.5dB.

Thankfully though, Corsair keeps the fan quite a bit away from this. According to Corsair's own diagram on the back of the box, it only hits headache inducing when its running at close to the full 1,000W. At 50 percent load it sits just under 25dB, which isn't anywhere near silent, but it's not intrusively loud either - it should easily blend in among hard drives and case fans.

As PSUs are typically limited by their only moving part - the fan. The ball bearing fan should last longer, and Yate Loon is certainly a decent (and popular) manufacturer. Unlike other larger 1,000W models though, Corsair does not feel the need to include a second fan to aid the airflow through the unit, even despite the fact it's longer than normal size.

This does give us some cause for concern, because the last CWT model we looked at was the Thermaltake Toughpower 1,500W with almost the same design, and this clearly overheated in some parts on very high load. The saving grace for Corsair is that this load was in excess of its 1,000W limit - we simply think Thermaltake pushed the design too far.

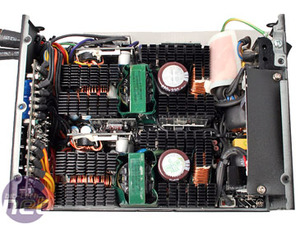

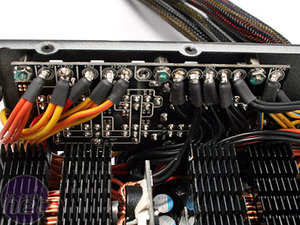

Inside you can clearly see the division down the middle - it's two PSUs on a single PCB. There are two transformers and coils doing the single AC-DC conversion for the 12V rail, then there's a smaller PCB for the 12V to 3.3V/5V conversion. This keeps the efficiency higher and makes best use of the limited space, and the space is very limited.

Corsair moulds the heatsinks around the components and stretches them above towards the fan for maximum cooling. They are all angled so that the airflow is directed out the back, and the small PCB that converts the 5V standby separately is placed at the very top in an effort to force the airflow downwards. In our opinion, this little PCB doesn't really cover enough to do this though.

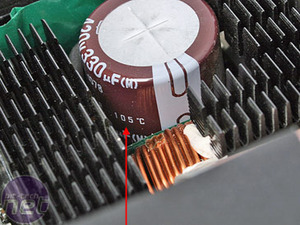

As with most CWT models the quality of manufacture is very good and there are plenty of solid aluminium capped capacitors nestled under things to withstand the high temperatures. The large main capacitor is also designed to withstand a 105C too, so it can take the sweat of being wedged in between heatsinks and hot components on all sides.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.